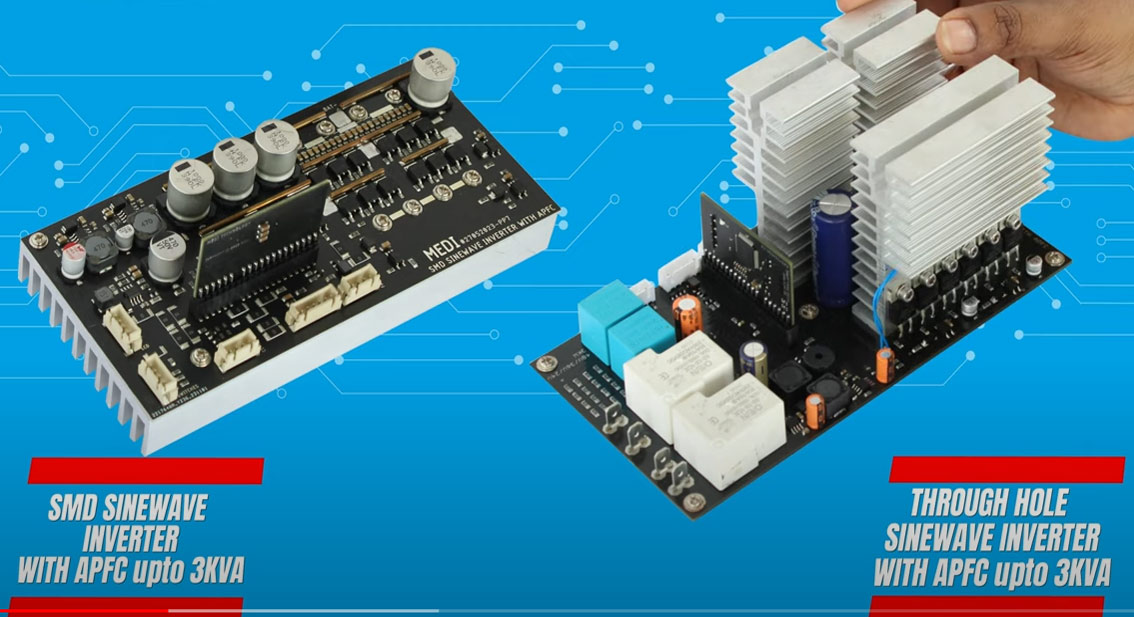

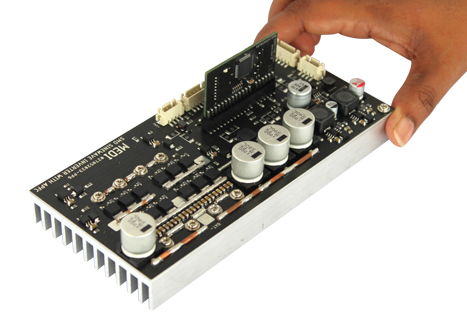

SMD Sinewave Inverter with APFC(Active Power Factor Correction) upto 3KVA

Highlights

- Fully SMD design. All components including the power MOSFETs are surface mount components. This is very easy for pick & place assembly.

- APFC (Active Power Factor Correction) charging and current harmonic reduction

- APFC charger will take very low current from the mains during charging.

- During APFC charging the current from the mains will be pure sinewave current unlike other inverters which have pulsating current with very high peak current.

- Synchronous rectifier topology used in charging means there is no diode drop, during charging MOSFET is switching instead of diode. So high efficiency.

- Heat reduction during charging due to APFC charging and high current charging >35A suitable for LITHIUM batteries.

- Soldering of MOSFETs to aluminium PCB gives excellent heatsink capability compared to conventional screw tightening of MOSFETs.

- During power failure when inverter is working it will disconnect both phase and neutral from the grid so there will not be any possibility for return current flow from the neutral / phase towards grid.

- Fast change-over in less than 2 millisecond so computer will not reboot.

- 4000V galvanic isolation for battery from AC input & output.

- Reduces man hours of fitting mechanical parts like MOSFETs on the heatsink, fitting heatsink to the PCB etc.

- Reduces failure rate and increases reliability due to no mechanical errors caused by manual fitting.

- Pick and place production results in quick turnaround time.